With the development of society, people’s demand for water is getting higher and higher, and the equipment used is more and more advanced. Many people have begun to use the reverse osmosis membrane for water purification and efficient filtration. Reverse osmosis membrane is an artificial semi-permeable membrane with certain characteristics made by simulating biological semi-permeable membrane. It is the core component of reverse osmosis technology. To play a better role, the correct use method can improve the efficiency and extend the service life. There are so many details that need to attend when using the 8040 reverse osmosis membrane.

1. The water production listed in the table is an average value, and the water production error of a single membrane element is within ±15%.

2. The test conditions are not the best use conditions, please consult the technical staff for details.

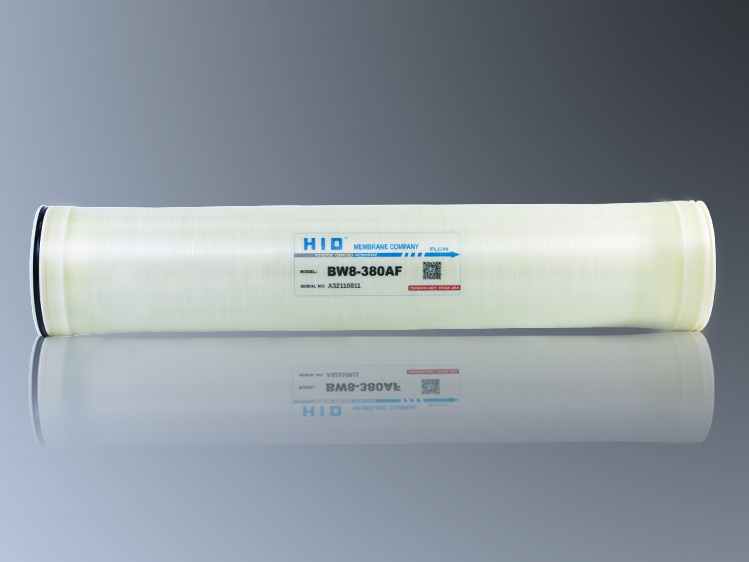

3. The membrane element is equipped with a pressure vessel with a nominal inner diameter of 8 inches.

4. Before the RO system starts to start, the system pretreatment and debugging, component filling, instrument calibration, and another system testing should be completed.

5. The inlet water of the RO membrane element should be gradually boosted, and the time for boosting to normal operation should be no less than 60 seconds.

6. The newly installed membrane should be flushed under low pressure for more than two hours, and the RO pure water should be discharged.

7. Take care to avoid back pressure on the waterside of the product.

8. All membrane elements have been strictly tested before leaving the factory, and use 1.0% sodium bisulfite (10% propylene glycol antifreeze in winter) solution for storage treatment, vacuum packaging, and the outer packaging is a cardboard box.

Post time: Feb-02-2021